- Published on

Microstructure analysis of sprayed casting mold coating with micro CT

- Authors

- Name

- Universal Lab

- @universallab

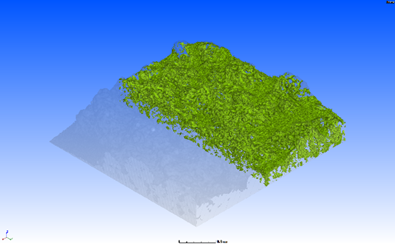

Insulating casting mold coating is a layered material for permanent mold. Normally, the mold coating is sprayed onto the mold with a spraying gun with gas-liquid flow nozzle. This atomization process will transfer the liquid mold coating material into a porous coating made of ceramic particle, as shown as in Figure 1.

This temporary layer protects the mold from chemical, thermal and mechanical shock from the molten metal. Moreover, the insulation effect of sprayed mold coating depends strongly on the coating microstructure, such as ceramic particle size and porosity. Therefore, the coating microstructure analysis is essential for coating properties and atomization process optimization.

Micro CT is suitable for investigating the microstructure of the sprayed mold coating. In Figure 1, not only the concrete porosity but also the pores form and distribution can be analyzed in detail. This micro CT 3D imaging should be also suitable for the microstructure analysis of other porous material.