Ar lon Milling / Polishing

Instrument Type:

Leica EM RES102

Analytical Program:

Normal hard material (softer than W) -- 200 CHF/sample

Ultra hard material (W, diamond, SiC) -- 300 CHF/sample

Permanent magnetic material (NdFeB, CeB) -- 300 CHF/sample

Instrument Type:

Leica EM RES102

Analytical Program:

Normal hard material (softer than W) -- 200 CHF/sample

Ultra hard material (W, diamond, SiC) -- 300 CHF/sample

Permanent magnetic material (NdFeB, CeB) -- 300 CHF/sample

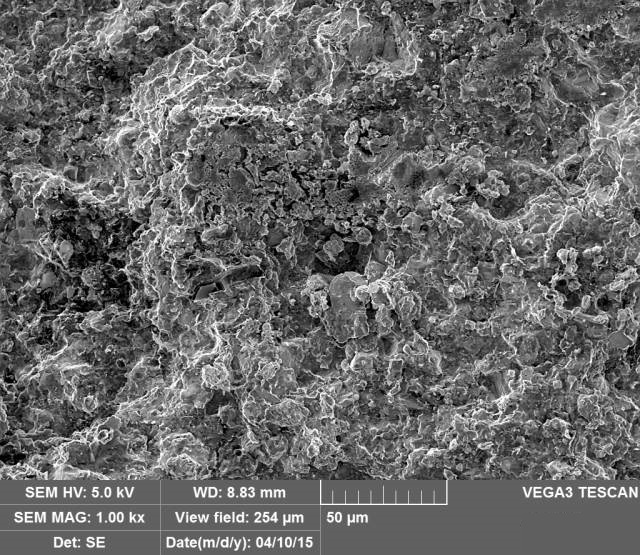

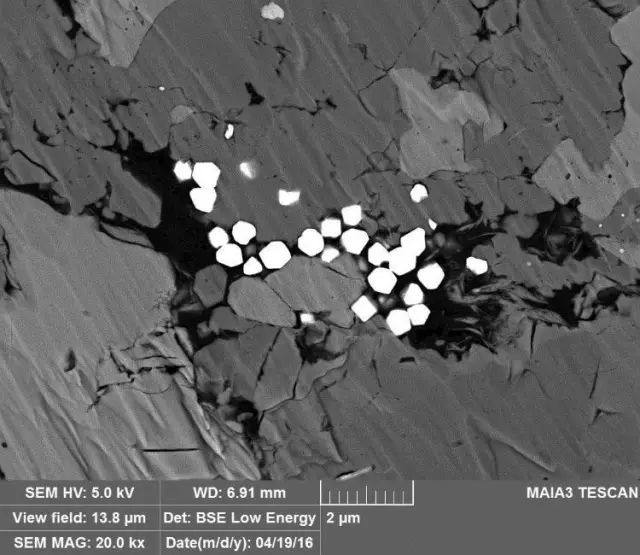

The argon ion polishing /milling is used for the preparation of samples for SEM, EPMA, EBSD, and other applications.

By bombarding the sample with an ion beam, a smooth sample surface can be obtained, providing a large observation area, clean results, and suitability for almost all materials, without causing mechanical damage to the sample.

By removing the damaged layer, high-quality samples can be obtained.

In contrast, samples prepared by mechanical grinding and polishing have rough, uneven surfaces, many scratches and damages, and unclear boundaries.

the sample should be pre-ground and polished, the sample should be flattened, and the upper and lower surfaces of the sample should be parallel.

The polished surface of the sample should be ground with at least 4000 grit sandpaper to ensure it appears smooth and not rough when viewed under a microscope.

For block-shaped samples, the diameter should not exceed 30mm, and the thickness less than 20mm. For powder samples, a minimum of 10g is required.